Technology

NGSG SMART (System Management and Recovery Technology) System

INNOVATIVE CONCEPT – Avoid shutdowns by steering away from them automatically:

- Suction pressure

- Discharge pressure

- Interstage pressures

- Gas discharge temperatures - Outlet interstage

- Horsepower

- Rod load

SECONDARY IDEA – Maximize performance automatically:

- Maximize flow with varying pressure conditions – up to driver Hp limits

- Control dewpoint to increase/decrease condensate at each stage outlet

- Reduce blowdown emissions (fewer shutdowns & multistage blowdown/pressurized restart)

- Catch engine before detonation shutdown by reducing load until problem goes away

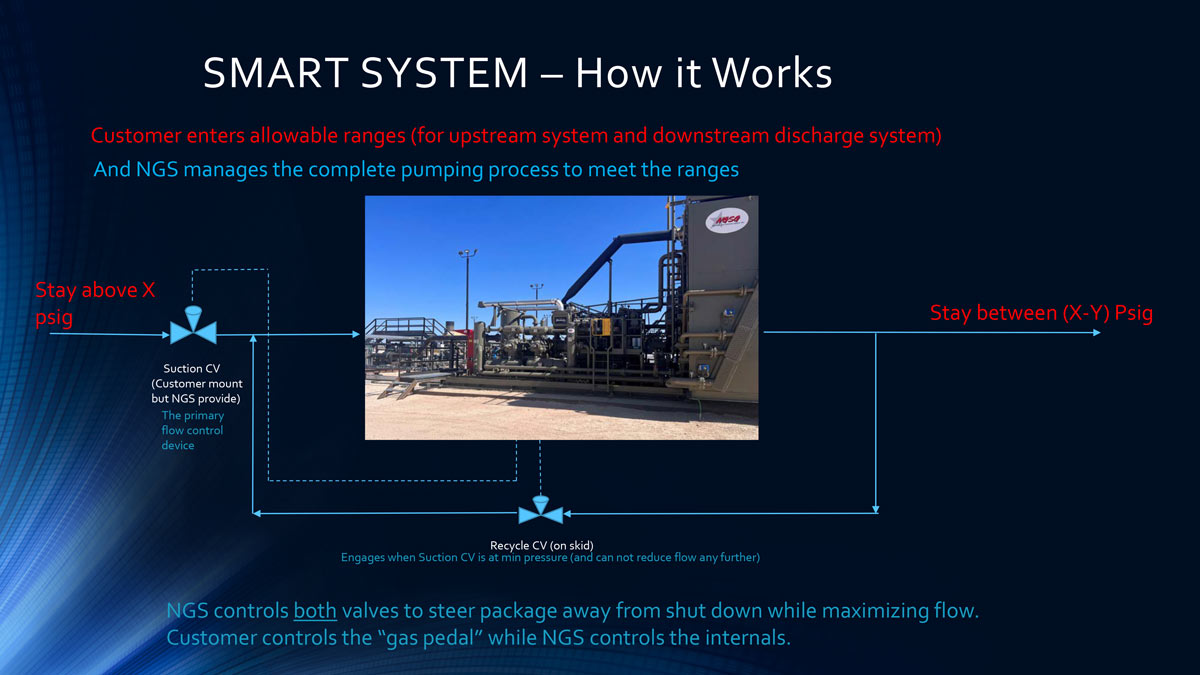

How it Works

SMART Compressor Package Advantages Over Standard Compressor Packages

| Operational Aspect | SMART | STANDARD | Notes |

|---|---|---|---|

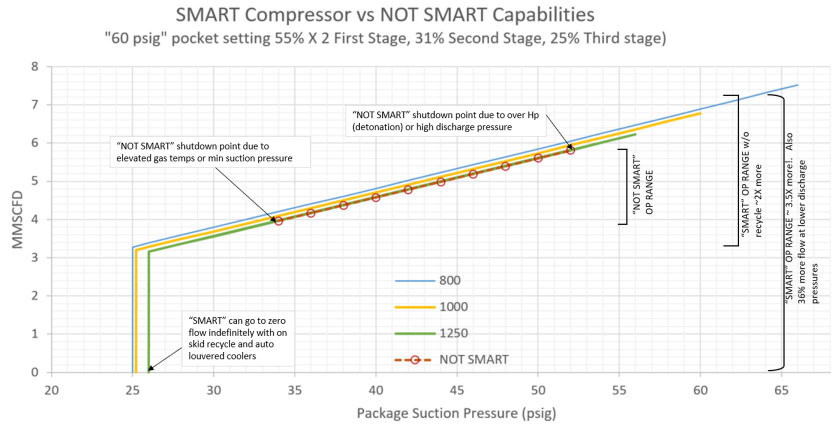

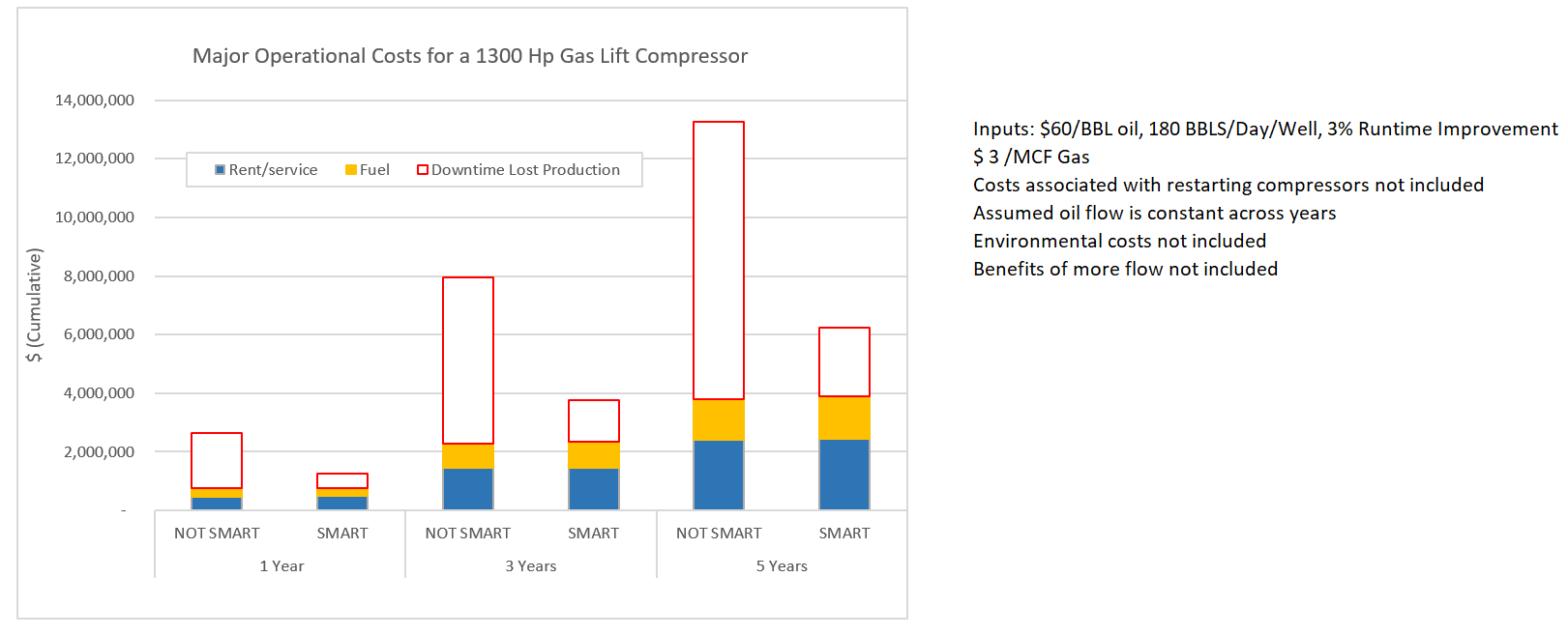

| 100% flow turndown - keeping the compressor running through upsets without shutting down | ✓ | SMART allows continuous operation through all flow upsets - upstream supply systems or downstream wells and sales points etc. No need to use manpower to restart because machine stays running. The standard package has less than 15% flow turndown capability. And if auto pockets and recycle are added, it gets only ~30-40% turndown in reality. With standard packages, the flow shutdowns are usually attributed to the customer and excluded from the supplier's Mechanical Availability responsibilities. | |

| Ability to run in low temperature winter periods without condensate hydrate plug formation | ✓ | Most of the SMART equipped packages can operate indefinitely down to 20-25°F ambient temperature. Standard packages begin to freeze at around 40°F ambient. Even when a hot gas bypass is added, freeze ups continue to occur in the cooler. Despite winter coming every year, these shutdowns are usually attributed to the customer and excluded from the supplier's Mechanical Availability responsibilities with the standard package. | |

| Avoid shutdowns from suction or discharge pressure excursions | ✓ | SMART system package handles pressure excursions and keeps the package from shutting down. Standard packages have no such capability. The SMART package also counts dumps per day. | |

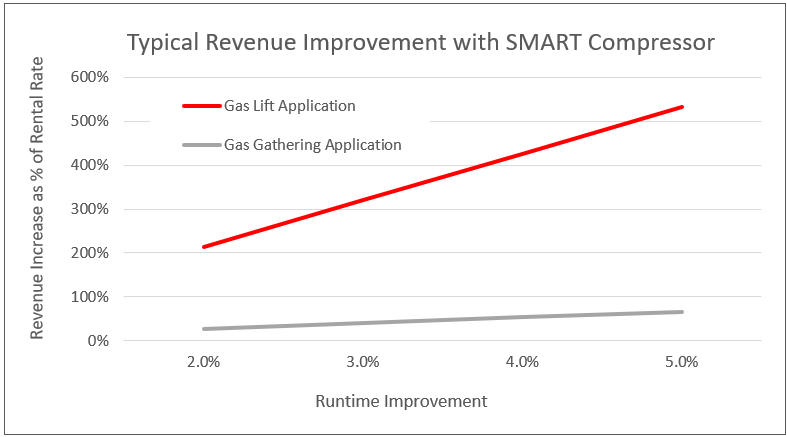

| Maximizes flow when the pressures change to maximize revenue | ✓ | The SMART machine always adjusts to maximize gas volumes - up to the engine's maximum rating. Standard packages pump about the same amount of gas even when discharge pressures fall and the engine had additional load available. | |

| Avoid shutdowns from temporary fuel gas upsets via unloading engine | ✓ | ✓- | Some larger standard engines adjust timing to avoid a shutdown but is is not as effective as temporarily unloading the engine. The SMART system utilizes both. |

| Ability to control how much liquid is dumped vs transferred downstream | ✓ | Most SMART packages control discharge temperature for each stage via the PLC so that the amount of condensate generation can be controlled. Standard compressors have minimal temperature control capability if any. The SMART package also counts dumps per day. | |

| Needs no internal shutdowns programming with pocket changes | ✓ | SMART packages calculate and keep track of all parameters for shutdowns. The standard package requires simulation to estimate where the limits will be and set them conservatively. Many suppliers forget to change internal shutdowns after adjusting pockets resulting in unnecessary shutdowns. | |

| Minimal customer programming to avoid compressor shutdowns | ✓ | With SMART, the station programming only needs to provide the suction and discharge targets and limits. Customer does not need to program to avoid the many compressor internal shutdowns. | |

| Includes suction and recycle control valves | ✓ | ✓- | The SMART package provides both valves with the recycle being located on board which minimizes the site construction by customer. In addition, control of both valves is fully integrated with engine load, discharge temperatures, rod loads and pressure information in the PLC. Some suppliers include these valves for an extra charge and provide a minimal level of integration to the automation. |

| Minimizes blowdown volumes | ✓ | The SMART package shuts down less and therefore will vent less gas associated with blowdown and startup. Furthermore, it routes discharge gas trapped in the case during shutdown to the suction header to minimize blowdown gas volumes. Lastly, it stops venting when the case pressure is low enough to restart. | |

| All these aspects increase customer profitability through additional revenue and reduced manpower devoted to compressor restarting | |||